"sony1492" (sony1492)

"sony1492" (sony1492)

06/09/2019 at 18:17 • Filed to: SC400

2

2

2

2

"sony1492" (sony1492)

"sony1492" (sony1492)

06/09/2019 at 18:17 • Filed to: SC400 |  2 2

|  2 2 |

U nused Harbor Freight 1 ton engine stand for $60. Both 1uz’s aught to be rebuilt so this is a good first step.

Rebuilds a ways out though because the of textbooks/ the mini needing $600 in immediate maintenance.

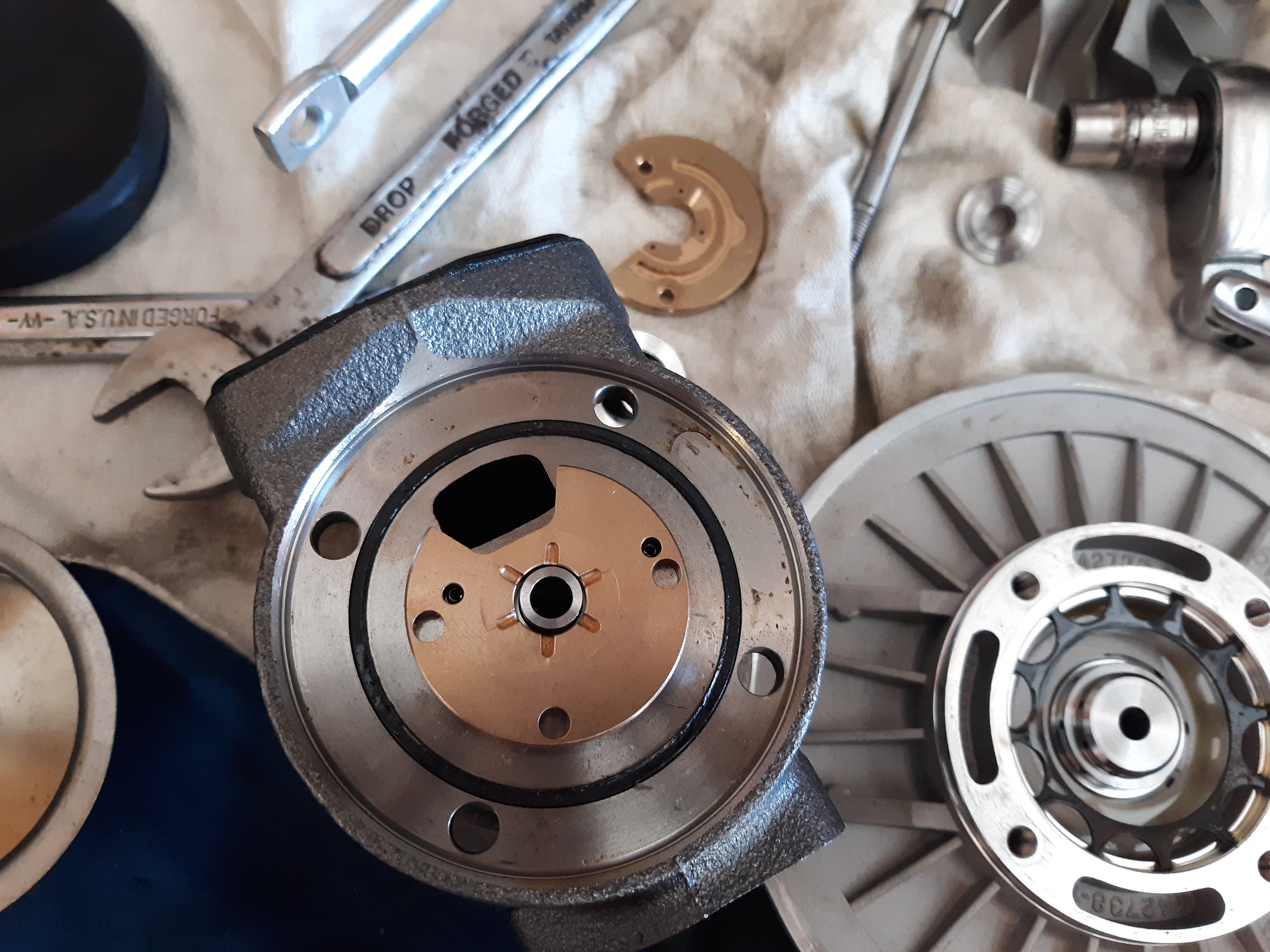

So with a bunch of time on my hands while money is being spent elsewhere the Lexus is getting alot of little things done. Today its rebuilding the new ebay turbos with better parts, in this case stagger gap shaft seals and 360° thrust washers instead of 270°.

Stripped the wheel wells of most of their undercoating, this saves time down the line when or if I seam weld the chassis.(I’m not ready to take the HVAC out for the welding)

A hood vent will be in order since the underside of the front end is getting a flatbottom. Cant decide on a design, the drop in scoops would probably function best but the tvr style gills would be less offensive on the sc400's hood. Idea dump:

What do you think?

Future Heap Owner

> sony1492

Future Heap Owner

> sony1492

06/09/2019 at 23:13 |

|

Huh, where on a turbo does the thrust washer go? On the turbine side? Is it 270° from the factory to allow some exhaust gas to escape?

sony1492

> Future Heap Owner

sony1492

> Future Heap Owner

06/09/2019 at 23:21 |

|

On the charge air side, I believe 270 is used because it's easier to manufacture by just cutting out the lower portion that drains into the return(large hole up to top) rather then more elaborate internal passages. I could be wrong